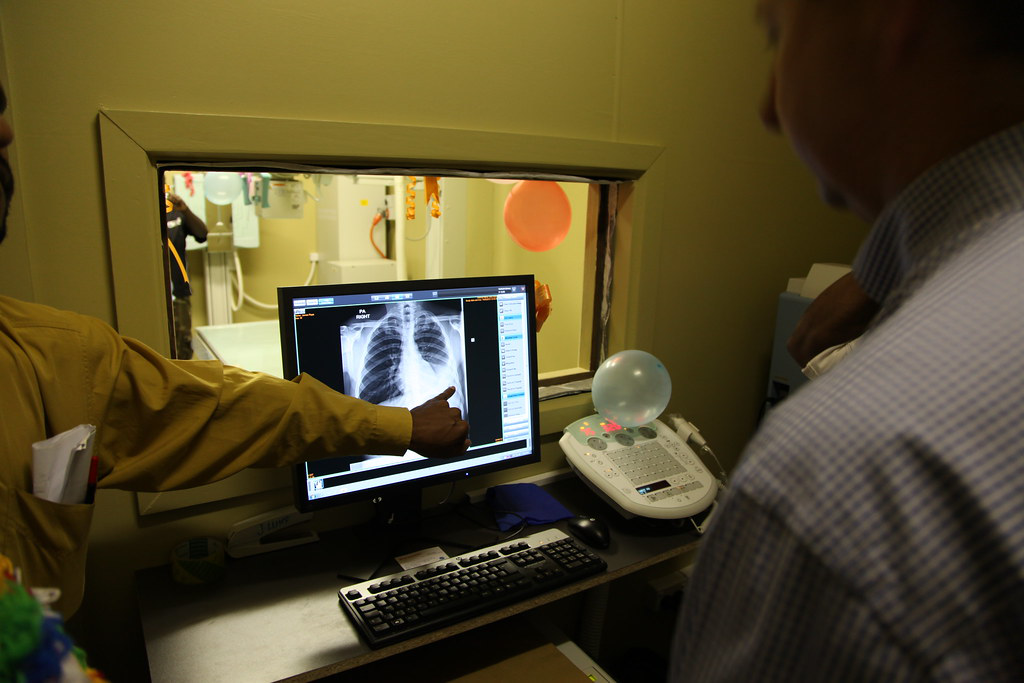

It’s impossible to overstate the importance of diagnostic imaging when it comes to the provision of health care today. It serves as a precursor for determining whether a patient needs surgery or therapy.

In the last few decades, the prevalence of chronic diseases has grown drastically all over the globe, leading to an increased number of diagnostic imaging procedures being performed every year. This growing need for precise diagnosis has led to the advent of advanced medicalimaging technologies including devices such as digital radiography flat panel detectors.

Flat panel detectors FPDs are digital radiography (DR) devices that either convert x-rays into an electric charge (direct conversion) or light (indirect conversion) which is then read out through TFTs (Thin Film Transistors). The imaging principles used in FPDs are similar to those of imaging sensors used in digital photography and video cameras.

Flat panel detectors offer a number of advantages over analog radiography equipment. These include durability, portability, time saving, cost savings, better image quality, and lower radiation doses.

There are two types of flat panel detectors: Direct and Indirect Let’s take a look at how they work.

Direct Detectors

Direct conversion detectors use amorphous selenium or other types of photoconductors for capturing incident X-ray photons, and directly converting them into an electric charge. The photons of the X-ray incident upon a layer of a-Se generate electron-hole pairs through an internal photoelectric effect. The electrons and holes are drawn to the corresponding electrodes by applying a bias voltage to the depth of the layer of selenium, which results in the generating current being proportional to the irradiation’s intensity. Underlying readout electronics, which are generally a TFT array, are then used to read out the signals.

Indirect FDPs

Indirect FPDs include a layer of scintillator material (generally either cesium iodide or gadolinium oxysulfide) which facilitates the conversion of X-rays into light. Cesium Iodide (CsI) is better. There’s an amorphous silicon detector array placed directly behind the scintillator layer. The manufacturing process of the scintillator layer is similar to the one used to make LCD monitors and TVs. And similarly to a TFT-LCD display, millions of thin-film transistors containing pixels form a grid pattern in the scintillator layer on the glass substrate. Just like the image sensor chip of a digital camera, a photodiode is contained in each pixel that generates an electrical signal that’s proportional to the light created by the scintillator layer portion situated in front of the pixel. The signals created by the photodiode are than encoded and amplified by electronics placed around the sensor array to produce an accurate digital version of the x-ray image.

If you’re looking to invest in high quality flat panel DR system for your medical imaging facility, get in touch with us at ExamVue digital X-rayl. Our superior digital image solutions have helped radiologists from all types of medical facilities, offering improved performance and results for their diagnostic imaging needs.